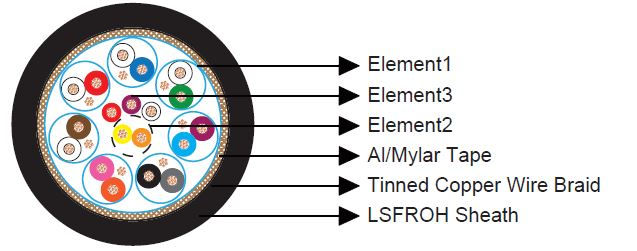

DVI Rolling Stock Cable (7P+1P+3C)

- hujayasupply

- Sep 10, 2019

- 2 min read

Construction:

Element 1: 7PR×24AWG(Cu/PE/Individual Al-mylar Screen+ TC Drain Wire) Conductor Stranded annealed tinned copper wire, 7/0.20mm Insulation Polyethylene. Thickness 0.28mm. Outer diameter 1.16+0.05mm Core Identification 1PR=White/Brown; 2PR=White/Red, 3PR=White/Green; 4PR=White/ Blue, 5PR=Grey/Black, 6PR=Pink/Orange, 7PR=Light Blue/Purple Twisting The cores shall twisted together in pair, the lay between each twist shall not exceed 100 mm Individual Shield Aluminum/ mylar laminated tape applied with the metallic side down in electrical contact with a 24AWG tinned copper drain wire (7 strands formation). A 23 micron mylar tape is applied over the screening tape with a minimum 25% overlap.

Element 2: 1PR×24AWG(7/0.2mm) Stranded TC/PE Conductor Stranded annealed tinned copper wire, 7/0.20mm Insulation High density polyethylene. Thickness 0.15mm. Outer diameter 0.9mm Insulation Color Yellow and orange Twisting The cores shall twisted together in pair, the lay between each twist shall not exceed 100 mm

Element 3: 3C×24AWG(7/0.2mm) Stranded TC/PE Conductor Stranded annealed tinned copper wire, 7/0.20mm Insulation High density polyethylene.Thickness 0.15mm. Outer diameter 0.9mm Insulation Color Red/Purple/White

Element Assembly Overall Screen Aluminum/ mylar tape Braid Shield Braid of tinned copper wire. Coverage ≥ 85% Outer Sheath LSFROH elastomeric sheath,Thickness 1.0mm. Outer diameter 12.5+1mm, other materail is optional Sheath Color Black or as per the client’s requirement

Physical Properties:

Temperature rating: -25°C to +80°C

Minimum bending radius: 3 x Overall Diameter

Electrical Properties:

Rated voltage: 30V

Max conductor resistance at 20°C: ≤89.2 Ohm/Km

Min insulation resistance: ≥100M Ohm/m

Test voltage: Min. AC 250V/1second

Nom. mutual capacitance at 1KHz: 57 pF/m

Fire Performance in General:

Vertical flame propagation for a single insulated wire or cable

EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2)

Vertical flame spread of vertically mounted bunched wires or cables

EN 50266-2-4 + EN 50305; IEC 60332-3-24; NF C 32-070 2.2 (C1); VDE 0472 Teil 804

Low Smoke Emission

EN 50268-2; IEC 61034-2; NF C 32-073 ;NF C 20-902; NF F 16 101; VDE 0472 Teil 816

Halogen Free

EN 50267-2-1; IEC 60754-1; NF C 32-074; NF C 20-454; VDE 0472 Teil 815

Low Corrosivity (Acidity & Conductivity)

EN 50267-2-2/3; IEC 60754-2; NF C 32-074; NF C 20-453; VDE 0472 Teil 813

Low Toxicity

EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853

Smoke Index

NF F 63 808; BS6853; NF F 16 101

Fire Performance Relating to Rolling Stock Application:

DIN 5510-2

BS 6853

NF F16 101

NF F 63 808

Comments